The introduced centrifugal equipment is based on unique design concepts, which were patented and implemented into our centrifugal machinery. The equipment, being produced at

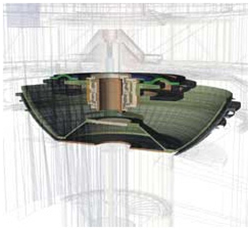

Gas-static bearing

The basic element of the equipment is our patented air supporting node / gas-static bearing, which provides for technical efficiency and excellent process capabilities.

A gas-static bearing comprises hemispherical elements which disperse under pressure of the air flow and form “a gas bearing”. The supporting part of the bearing node (stator) is static. The dynamic part of the node comprises an accelerator and a cardan shaft mounting rod which provides for rotation of “rotor-accelerator” system. There are no friction forces (only air friction), vibration and mechanical interworking between the system elements.

The gas-static bearing is a self-balancing system. Due to special construction of the gas bearing and drive, the rotor has three degrees of freedom. The rotor takes optimized attitude position under the influence of the resulting forces (lifting air force, cardan shift tension, accelerator weight and aerodynamic forces of high and low pressure zones leveling) regardless of direction and loading conditions and ensures stable and regular performance of the equipment at high imbalance degree and accelerator dynamic load.

The units of the gas-static bearings are equipped with:

–Contact warning system;

– Protection from extreme misbalance overloading which can be caused by uncrushable oversized material feeding in the crushing equipment;

- Safe emergency stop system;

The construction reliability is also proved by the fact that this technology is used in the development and effective application of centrifugal stands for military and space equipment testing with marginal overload value up to 500g. The gas-static bearing appliance ensures high technical parameters of the grinding equipment and substantional reduction of operation cost, labour input and servicing intervals.

Accelerator

Accelerator is the main working body of crushing and milling equipment, it ejects material through special guiding channels. The accelerator design allows self-fettling of the guiding channels and the main wear areas, and a possibility of simple multiple repairing. The accelerator total weight is 100-

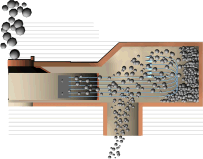

Crushing chamber self-fettling

In most cases breakage of material is made using “a stone on a stone” concept. This technology allows substantial wear parts cost reduction.

Breakage is the result of impacts against accumulated material layer in the fettling area and particles inter-impacts. In contrast to other crushing machines, centrifugal crushers DC ensure high fragmentation due to high-speed ejection provided by gas-static bearing system.

Operating principle:

Air pressure in the chamber is generated by high-pressure fan; the pressure is needed for the rotor to float and “gas bearing” of the system to arise. The shaft drive sets in motion the working body of the crusher by means of accelerator rotating. The raw product is fed to the accelerator separating cone through the chute. The raw material is distributed among the channels; it fills special pockets of the accelerator, making a fettling layer, under the influence of centrifugal forces.